ALEA casting software optimizes time, materials and production costs for all types of alloys

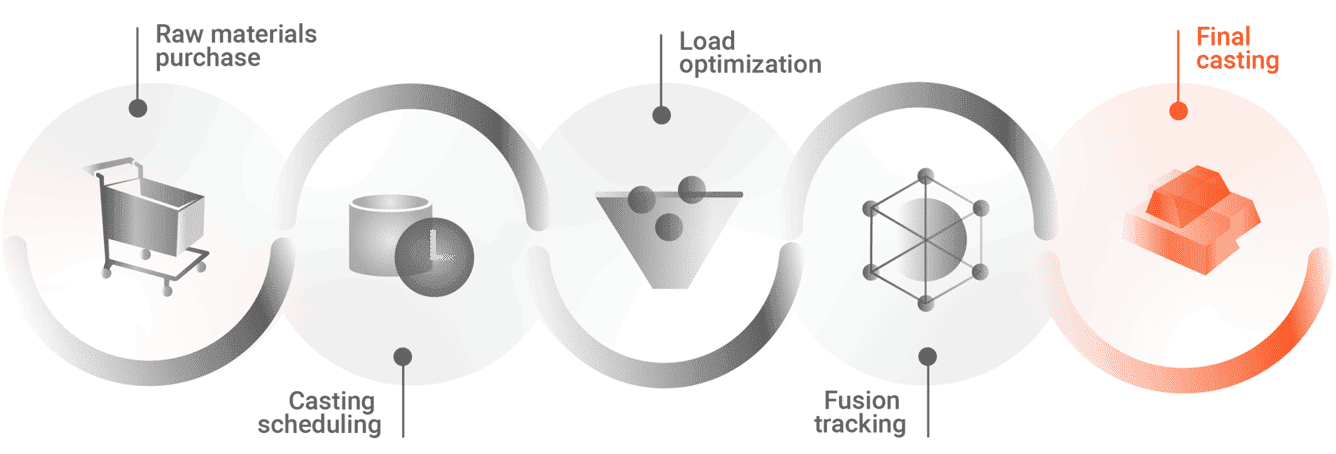

Complete control of the melt flow from raw material purchase to final casting

Find out how much you can save in your foundry with ALEA casting optimization software

Global

optimization

ALEA optimizes loads for a complete casting program, including ongoing inventory, purchase orders and recirculating forecast.

Multi-furnace /

Multi-flow

Adaptable to any scheme (melters, casting machines, maintainers, ladles…), simulating bath feet and contaminations in alloy changes.

Multi-profile /

Multi-user

Interface adapted to each profile (purchasing, casting, laboratory…). Each user identifies quickly and intuitively the information.

Control of chemical variability

ALEA eliminates rejections and minimizes chemical adjustments taking into account composition variability.

Integrated with the entire plant

ALEA communicates with any device (spectrometers, weighing scale, loading systems…) and system (ERP, MRP, MES…) automating data capture and eliminating human errors.

We automate data capture and apply Artificial Intelligence to achieve maximum excellence

EACH PROJECT IS UNIQUE

With the confidence of our company’s expertise in industrial casting software development

Training

Technical Support

Software Upgrades